Building a smarter industrial robot

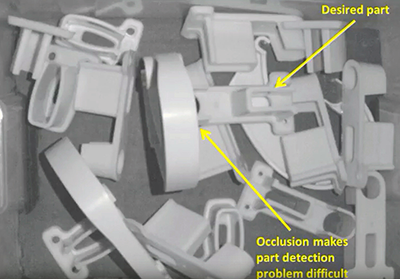

New research by Professor S.K. Gupta (ME/ISR) and his students may provide a path forward towards smarter, more versatile industrial robots and more interesting duties for the humans who work with them. Currently, industrial robots are used mostly for high-volume, reliably repetitive tasks with unchanging, tightly proscribed parameters, such as automobile assembly lines. Such robots are custom-built and programmed specifically for the tasks at hand. While they excel in such environments, these robots are limited in their ability to assess whether they can successfully complete tasks. So if, for example, the parts they are working with aren’t placed in the exact right position, the robot doesn’t know it should stop what it’s doing. A chaotic mess can result—one which humans must then fix. Because of economic considerations, robots are not used in factories until high task reliability can be ensured. A better model would be to give robots the ability to assess whether they can successfully complete a task, and if they sense they cannot, to stop and ask a human for help. Gupta’s research team has developed RoboSAM (ROBOtic Smart Assistant for Manufacturing), a robot that can estimate the probability it can complete a task before beginning it, and ask a “human on call” for help if necessary. The team has successfully demonstrated RoboSAM in a “bin picking” situation where the robot needs to find a desired object in a bin of similar objects, successfully pick it up, and deliver it to another area in a specific placement. If the robot is not sure whether it can complete the task (for example if the part is “buried” within the bin), it is able to take pictures of its situation and call a remotely located human (the “human on call”) for help. The human then suggests to the robot what it should do to complete the task.

This work is the beginning of providing a better economic model for deploying robots, especially for small- and medium-sized manufacturing companies, Gupta believes. “In most situations, providing task assistance help to robots is much more cost-effective than recovering from a system shutdown, and it enables humans to move from doing dull tasks like monitoring and clean up to more challenging work like helping robots with the tasks with which they struggle.” The work was presented at IEEE Robotics and Automation Conference in Gothenburg, Sweden on August 28, 2015. This research is funded by NIST and NSF. Gupta is the director of the Maryland Robotics Center. You can read Gupta’s thoughts about the project on his blog Pursuit of Unorthodox Ideas.

Related Articles: September 8, 2015 Prev Next |