|

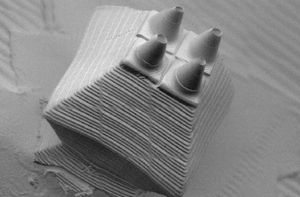

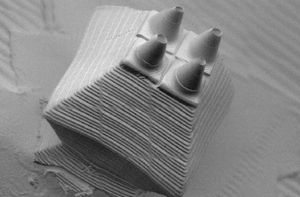

Scanning electron microscope image of a flexible injector made using a hybrid fabrication process to allow sharp and effective injection needles. Scanning electron microscope image of a flexible injector made using a hybrid fabrication process to allow sharp and effective injection needles.

|

“I am proud of my team for advancing the ingestible capsule technology to deliver medicine when and where it’s needed most,” said Dr. Ghodssi. “Thank you to ACS Applied Materials & Interfaces for featuring this work, which has the potential to greatly improve the lives of those living with GI tract conditions like Crohn’s disease and ulcerative colitis.”

The team used a hybrid 3D printing approach to fabricate the capsule so it could support large drug loading volumes and fine-scale delivery precision. The new approach was inspired by previous ingestible actuation technologies.

“This advancement is expected to drastically improve the control of localized drug therapy,” said first author Dr. Joshua Levy, a researcher in MSAL and an alumnus of ISR's doctoral program. “It will lead to meaningful improvements like fewer side effects and more effective treatments.”

|

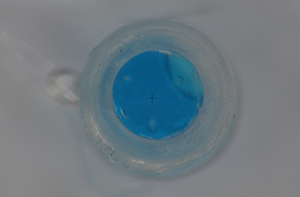

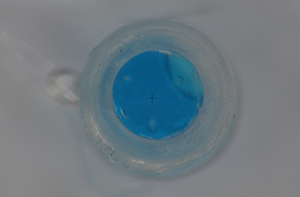

Diffusional release of model drug from a rigid injector for prolonged and controlled treatment of GI disease. |

The paper represents the latest advancement in ISR's extensive body of work on ingestible diagnostic and therapeutic systems. Prior MSAL-led research has focused on real-time sensing for gut health monitoring, including wireless bioimpedance sensors and gas detection tools integrated into swallowable capsules.

This research was supported by the National Science Foundation and conducted in collaboration with colleagues in electrical engineering, materials science, and biomedical engineering. Dr. Ghodssi serves as the lab's director and has guided much of the interdisciplinary effort behind these innovations.

The work exemplifies ISR's commitment to systems-level solutions in healthcare technology, combining design, fabrication, sensing, and actuation into integrated, patient-centered platforms.

|