No More Broken Antennas

Imagine a trip to the carwash without that feeling of panic when you realize you’ve left your radio antenna up.

That worry could become a thing of the past thanks to a new, flexible material developed by University of Maryland engineers that can be used to manufacture radio antennas that bend, but do not break.

The new material, a lightweight, plastic-like composite, will also render rigid cell-phone antennas obsolete and make future antennas smaller and more efficient.

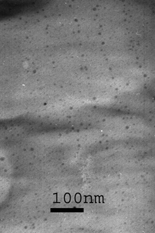

Peter Kofinas, an associate professor of chemical and biomolecular engineering at UM's A. James Clark School of Engineering, developed the material in a "chemistry shake-and-bake process" resulting in a self-organizing polymer containing nanometer-sized particles of two metals, iron and strontium. Chemical engineering undergraduate student Joshua Silverstein and graduate student Ta-I Yang also worked on this research.

The substance possesses magnetic and dielectric properties and can be used to make antennas that can be formed into any shape.

"The new material will allow for more freedom in the creation of the next-generation of devices, which will have lighter, smaller, more efficient design and aesthetic appeal now that a straight, brittle metallic antenna does not have to be incorporated," Kofinas says.

For instance, by making a cell-phone case out of this material, the case could then become the antenna, resulting in a smaller cell phone with better reception, he says.

Kofinas' work is still in the research stage, but the U.S. Air Force is interested in the material for use in protective covers for radar equipment and other types of shielding for electronics. The Air Force recently awarded Kofinas a $367,000 grant for further research.

April 11, 2006 Prev Next |