BIOE Alum's Company Releases Bleeding Management Tech Nationwide

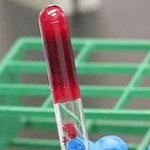

Rapid-Seal, a new antibacterial gel able to stop bleeding in seconds that was developed by Medcura, Inc., a company founded and fostered at the University of Maryland (UMD) is now available through Amazon and at a leading chain of pharmacies. The technology behind Rapid-Seal was born in Department of Chemical and Biomolecular Engineering Professor Srinivasa Raghavan’s Complex Fluids and Nanomaterials Lab, where Raghavan and his team study the spontaneous self-assembly of molecules and nanoparticles and use this behavior to create new “smart” materials. The product uses a proprietary modification of chitosan, a nontoxic, biodegradable biopolymer found in the shells of crustaceans and certain plants, to seal minor cuts and scrapes. Raghavan and his lab - which has launched three startup companies and filed for more than 20 patents - had been working on chitosan since 2003. “It was scientific curiosity,” says Raghavan describing what inspired the technology behind Rapid-Seal. “We had modified the polymer chitosan, and we wanted to test what would happen if we added it to blood. When Matt Dowling joined our lab in 2005, he quickly made a remarkable discovery.” At that time, Dowling was a first-year Ph.D. student in the Fischell Department of Bioengineering (BIOE) and a recipient of the prestigious Fischell Fellowship. Since 2003, BIOE has awarded the Fischell Fellowship to innovative graduate students interested in applied research and product design in the biomedical industry.

“When our body clots blood at the site of an injury, it again involves the conversion of blood to a gel,” Raghavan explains. “So, it occurred to us that our blood-gelling polymer could potentially stop bleeding from wounds.” Dowling and Raghavan worked with faculty at the University of Maryland School of Medicine and found that their polymer could indeed stop bleeding from even the most severe injuries. In 2009, the team was awarded UM Ventures’ Invention of the Year Award for their chitosan-based solution to bleeding. Dowling then founded Medcura, Inc., which produces Rapid-Seal and other bleeding management products. Medcura received initial research and development funding from the Maryland Industrial Partnerships (MIPS) Program, which paved the way for further studies with support from the National Science Foundation (NSF) Small Business Innovation Research (SBIR) program, the Maryland Biotechnology Center, and the Air Force Medical Assistance Program. Medcura then entered Mtech Ventures, an incubator of the A. James Clark School of Engineering’s Maryland Technology Enterprise Institute (Mtech) designed to help innovators build successful companies around technology-based innovations created at the University of Maryland. In 2015, the company received the first of many clearances from the U.S. Food and Drug Administration (FDA) for commercial uses of their products. At that time, Dowling and Raghavan were informed that theirs was the first product invented at UMD to have received FDA clearance. In 2016, the company hired Larry Tiffany, a serial life science entrepreneur and former executive at Gene Logic, followed by a $3.1 million initial round of financing that was led by early-stage investment funds and life science investors, including the Dingman Center for Entrepreneurship and UM Ventures. In 2017, Medcura received U.S. Food and Drug Administration (FDA) clearance for use of its advanced bandage for prescription and over-the-counter uses. Larger grants followed, including $3.4 million from the U.S. Army Medical Research & Medical Command to develop an implantable solution for prolonged field care. That solution, called LifeFoam, was awarded “breakthrough device” status by the FDA for the treatment of severe, internal, life-threatening hemorrhaging on the battlefield. In 2020, Medcura moved into UMD’s Discovery District, which offers flexible research and development space for growing ventures Now, this UMD-born technology is available over the counter and online nationwide, and Dowling is chief scientific officer and director of Medcura. “It’s incredible to see a Fischell Fellow go so far,” says Bill Bentley, director of both Mtech and the University of Maryland’s Robert E. Fischell Institute for Biomedical Devices. Bentley served as BIOE chair when Dowling earned his Ph.D. “The Fischell Fellowship was both inspired by and supported by BIOE and Fischell Institute namesake Bob Fischell, who wanted specifically to attract graduate students to our department who had a concrete desire to commercialize a product. We organized coursework, seminars, and laboratory experiences for these entrepreneurial students to help them on their path.

“Matt was the first recipient of the fellowship specifically recruited to move a particular technology forward,” adds Bentley. “It is especially gratifying to see how much he’s accomplished, both in terms of the early FDA approval and now an actual product on Amazon and on the shelves of pharmacies.” “The story of Medcura and Rapid-Seal is a terrific example of a fundamental discovery made in the lab that has been translated into a technology with the potential to save lives,” says Raghavan. “It all started with curiosity-driven scientific research, and required the persistence and perseverance of Matt Dowling to build his company up from scratch.” Medcura has seven U.S. patents and one granted European patent, with multiple patents pending. “I am so grateful to the Fischell Department of Bioengineering for preparing me to innovate and to execute on that innovation towards device development and product commercialization,” says Dowling, who joined the BIOE Advisory Board five years ago. “The commercial release of Rapid-Seal brings back the same feeling of excitement I had after getting our first FDA clearance on our vascular access patch for hospital use in 2015. Interacting with patients directly and hearing about how our products improved their quality of life is the best part of my job today. It’s incredible to be able to expand our reach and have the opportunity to help millions of people not only in routine day-to-day activity, but also those coming out of surgery, combat, or accidents, where hemostasis and wound treatment can make the difference between life and death.”

Related Articles: July 26, 2021 Prev Next |