Printed Solid-State Batteries

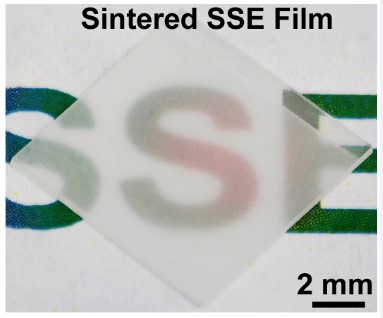

Lithium-ion batteries are widely used in portable electronic devices, electric vehicles, and grid-scale energy storage systems. Safety of the Li-ion batteries, however, has been called into question repeatedly over the past several years due to the conventional organic electrolyte causing fire and explosion in many cases. Ceramic solid-state electrolyte (SSE) thin film promises a viable solution to addressing the safety issue by blocking the lithium (Li) dendrite that causes the short circuit and thermal runaway, meanwhile offering high energy density for next generation Li-ion batteries. However, current SSE thin films have low ionic conductivities, ranging from 10−8 to 10−5 S/cm, which can be attributed to poor material quality. A research team led by Liangbing Hu at the University of Maryland (UMD) College Park recently developed a new method of printing and sintering a variety of SSE thin films. This work, entitled, “Printable, high-performance solid-state electrolyte films,” was published on November 18, 2020, in Science Advances. The team named this method 'printing and radiative heating' (PRH), which features a solution-based printable technique followed by rapid sintering. In a typical process, a precursor suspension is printed on a substrate, whose concentration and thickness can be adjusted. The high-quality and high-performance SSE thin film can then be obtained after rapid (~3 s) high-temperature (~1500°C) sintering, ensuring minimal Li loss and high crystallinity. This approach not only leads to dense and uniform microstructure for the SSE thin films, but also ensures superior ionic conductivity. Notably, the fabrication process – from precursor to final product – only takes ~5 min, which is ~100 times faster than conventional methods. In a proof-of-concept demonstration, the team showed a printed garnet-based SSE thin film to have high ionic conductivity of up to 1 mS/cm and excellent cycling stability. In addition, the PRH method enables many other designs such as complex multilayer assembly without cross-contamination during synthesis. It can also be extended to preparing other ceramic thin films, which opens up new opportunities in developing safe and high-performance solid-state batteries and other thin-film-based devices. For additional information: Ping, W., Wang, C., Wang, R., Dong, Q., Lin, Z., Brozena, A.H., Dai, J., Luo, J. and Hu, L. (2020). Printable, high-performance solid-state electrolyte films, 6, eabc8641, 2020, Science Advances. DOI: 10.1126/sciadv.abc8641.

November 18, 2020 Prev Next |