'Speedy Ceramics' Method Receives 2020 ARPA-E Award

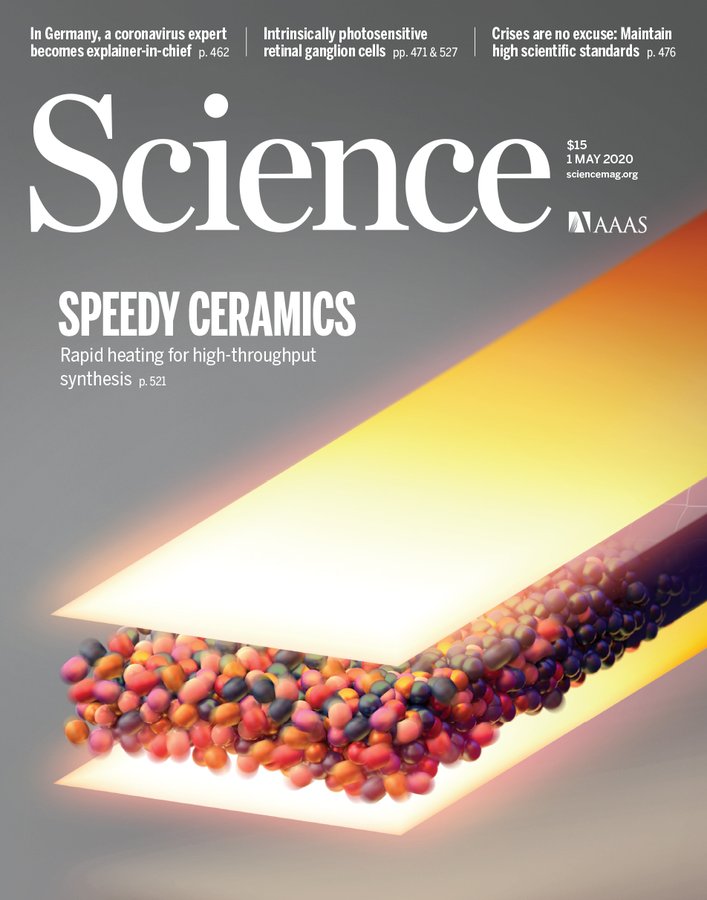

The U.S. Department of Energy (DOE) recently announced $33M in funding as part of the Advanced Research Projects Agency-Energy’s (ARPA-E) Rapid Encapsulation of Pipelines Avoiding Intensive Replacement (REPAIR) program. REPAIR seeks to eliminate the highest pipe rehabilitation cost components, excavation and restoration, by repairing pipes without their removal. The selected REPAIR teams are developing smart coatings, robotic systems to line the inside of pipes, inspection tools to verify the integrity of the pipes, and mapping tools to enable 3D renderings of pipes and adjacent underground infrastructure. Maryland Energy Innovation Institute (MEI2) faculty from the Departments of Materials Science and Engineering (MSE) and Chemical and Biomolecular Engineering (ChBE) will lead one of these newly funded projects along with partners from Diakont, Exelon and the University of Pittsburgh. The project proposes a multifaceted approach to develop a smart alloy coating for use in pipe-in-pipe configurations with UMD’s patented high-temperature sintering process, which recently made the cover of Science. A novel smart alloy coating is rapidly sintered with a high-temperature Joule heating bar directly from the alloy powders in approximately 10 seconds. The coating can be scaled to meet commercial market demands due to its high sintering density, mechanical strength, and self-healing properties. This technology is capable of generating new steel pipe to replace older infrastructure at a lower cost for gas service and with improved mechanical strength and corrosion resistance. "The University of Maryland is excited to apply its recently developed, innovative, high-speed, contact-less sintering technology to the challenges faced in the renovation of natural gas distribution lines through the ARPA-E REPAIR program," said Liangbing Hu, MSE Professor, Director of the Center for Materials Innovation and PI on this project. Paul Albertus, assistant professor in the UMD Department of Chemical and Biomolecular Engineering (ChBE), MEI2 Associate Director and Co-PI said, "In addition to providing a new, structural, 'pipe in pipe' that repairs the function of the original pipe, we are also developing a pipe material that will be compatible with either pure hydrogen or hydrogen/natural gas mixtures, which our partner Exelon and other utilities are interested in for future decarbonized gas supply infrastructure." The team is pleased to partner with Exelon, a Maryland-based company, as well as a UMD Clark School alumnus, Edward Petit de Mange (BSME 2001) at Diakont, and University start-up, HighT-Tech LLC. This is the 24th ARPA-E Award for UMD since the program’s inception in 2009. UMD is one of the top three public universities in ARPA-E awards and has received over $60M in ARPA-E funding.

August 27, 2020 Prev Next |