Battery Recycling

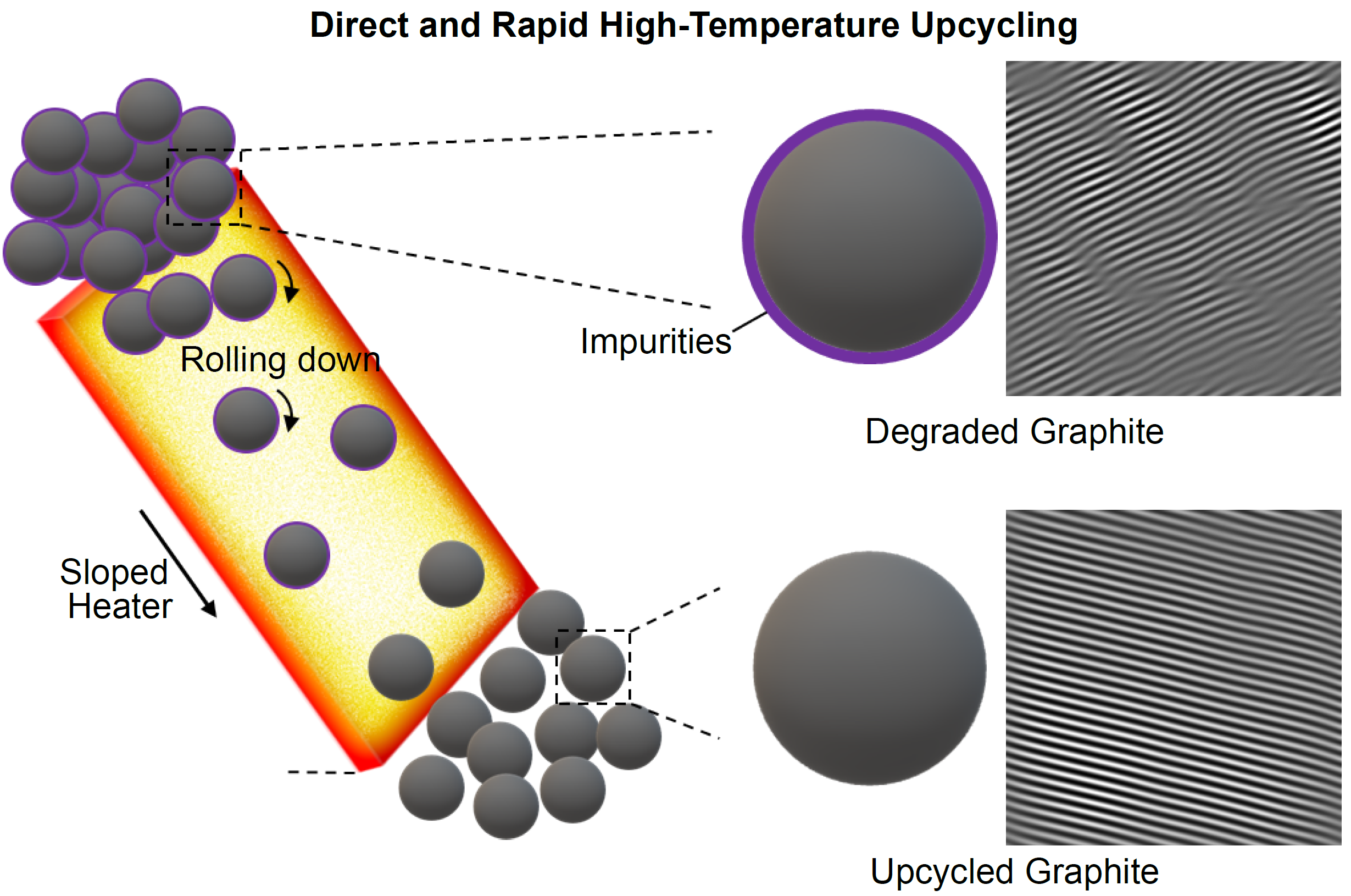

Lithium-ion batteries (LIBs) power numerous devices, including electric vehicles and demand is rising for LIBs amid climate change concerns. At the same time, scientists are grappling with a crucial environmental challenge—recycling spent battery components. For example, graphite anodes, a key component of LIBs, require recycling once a battery reaches its end of life. Yet current graphite recycling methods, which include acid leaching and furnace heating, come with their own set of environmental and operational problems such as pollution, slow processing, high energy consumption, and the challenge of preserving the graphite’s crystalline structure. Recognizing the urgent need for a rapid, energy-efficient, and scalable process to recycle graphite from spent LIBs, scientists in the Department of Materials Science and Engineering (MSE) at the University of Maryland, College Park (UMD) have broken new ground. Researchers have pioneered a unique method using an electrified carbon heater for the direct, rapid, and high-temperature (up to 3000 K) upcycling of degraded graphite. This process, completed within a single second, involves heating the degraded graphite powders as they roll down a sloped carbon heater, allowing for continuous and large-scale production of upcycled graphite. This innovative process successfully removes impurities, augments the degree of graphitization in carbon, and enhances interlayer spacing in the upcycled graphite—all of which are favorable conditions for lithium intercalation and deintercalation. Collaborating with colleagues from Virginia Tech, the team has demonstrated the upcycled graphite can be used to create a graphite anode with high capacity and retention. Notably, this method eliminates the need for chemicals in the upcycling process, offering a simpler and faster alternative to existing regeneration methods. It also holds the potential to be applied to upcycle other cathode and anode materials. This study was led by Prof. Liangbing Hu, the Herbert Rabin Distinguished Professor and director of the Center for Materials Innovation at UMD. Serving as the lead author of this work was Dr. Tangyuan Li, an assistant research scientist in Prof. Hu’s group. The research was also conducted in collaboration with Prof. Feng Lin and his team (Dr. Lei Tao) at Virginia Tech. For additional information: Advanced Functional Materials, 2023, DOI:

Related Articles: July 3, 2023 Prev Next |